Resource use and circular economy

Business strategy, business model and core values

Two of the core principles for succeeding in the transition to a more circular economy are prioritising renewable resources and using waste as a resource. This directly applies to Hafslund’s core business, which is the production of renewable energy. Hafslund produces renewable energy at its hydropower, wind power, solar power and district heating plants. Hafslund Oslo Celsio’s largest revenue stream is from district heating to residential and commercial buildings in Oslo, and the business plays a key role in Oslo’s circular energy system. Excess heat from waste incineration, data centres and sewage systems is used to produce renewable district heating. Hafslund Oslo Celsio owns and operates Norway’s largest waste incineration plant, and provides safe and environmentally friendly final treatment of residual waste that cannot or should not be recycled. In a fully developed circular economy, the vision is for zero waste. Before this is feasible in practice, energy recycling is the best alternative.

Impact, risks and opportunities

“Resource use and circular economy” is a material sustainability topic where Hafslund has both a positive and negative impact on people and the environment. Hafslund’s renewable energy production is an important driver of the transition to a circular economy. Electric power is produced using the renewable resources of water, wind and sun, which are part of the Earth’s natural cycle. Excess heat from waste incineration, data centres and sewage is used to heat homes and commercial buildings. Metals from the bottom ash following incineration are further processed into new raw materials.

Hafslund produces renewable energy, and ordinary operations do not involve the consumption of raw materials or other materials in hydro, wind or solar production. The district heating production is based on excess heat and therefore has no associated direct input factors, however the excess heat primarily originates from the incineration plants where sorted residual waste is the primary input factor. There is still some use of LNG, but this amounts to less than two per cent. LNG has an important emergency response function, but work is now being carried out on a potential modification of the boilers to enable these to also be fired using wood pellets, as well as LNG and biodiesel.

Hafslund Oslo Celsio’s waste incineration plants produce both hazardous and non-hazardous waste in the form of fly ash and bottom ash. The fly ash is sent to NOAH Langøya, which receives waste for treatment, neutralisation and disposal in accordance with the licences and frameworks issued by the Norwegian Environment Agency. The bottom ash is further treated by other operators, who extract metals and recycle these into new products.

Hafslund Eco Vannkraft’s current operations produce little waste. A few thousand tonnes of waste are generated each year. About half of this is recycled or reused, while the other half is recycled as energy through incineration or sent to landfills when possible. The latter primarily applies to concrete and rock mass that can be reused or recycled.

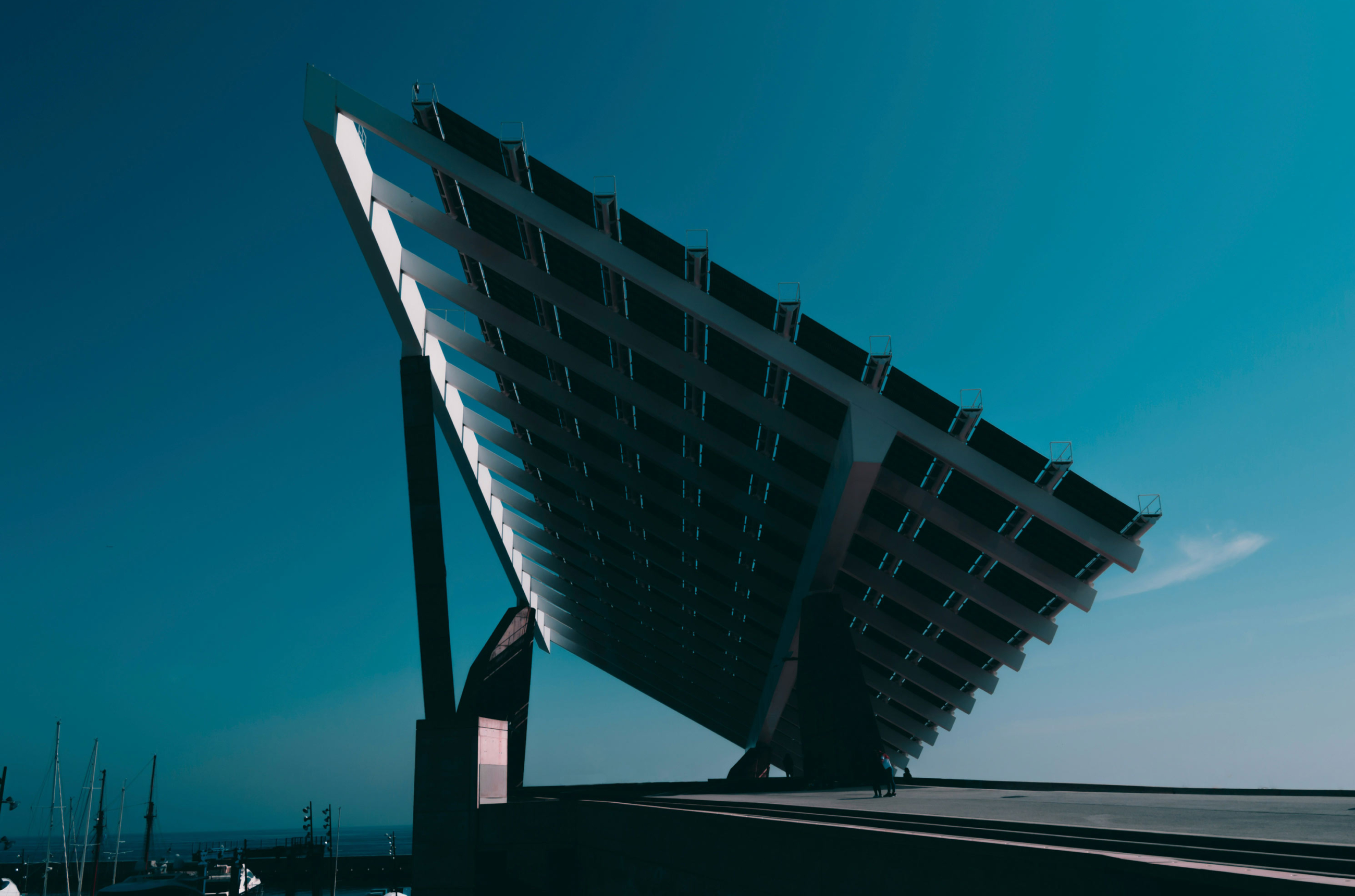

The transition to a fossil-free society will require new investments in the production of renewable power. Hafslund will continue to develop renewable energy in the form of new solar parks, new wind farms and new hydropower plants. Solar and wind power plants have shorter life spans than hydropower plants, and once this life span comes to an end, the plants need to be disassembled and removed. In order to reduce the pressure on virgin raw materials and minimise the negative impact on climate and nature, routines and systems for disassembly and removal must be established. This entails a plan for how materials and components are to be reused or recycled. In the instances in which this cannot be carried out, the alternatives are material recycling and thereafter potential energy recycling.

The table below summarises the Group’s most significant risks and opportunities related to “Resource use and circular economy”:

The transition to a fossil-free society will require new investments in the production of renewable power. Hafslund will continue to develop renewable energy in the form of new solar parks, new wind farms and new hydropower plants.

Significant risks and opportunities related to resource use and circular economy

| Risks | Opportunities | ||

|---|---|---|---|

| Disposal of components at the end of their useful life and costs of restoring facilitiesav levetiden og kostnader for gjenoppretting av anlegg | Reuse or recycling of components and materials | ||

| Waste generation and treatment | Lifecycle thinking for procurements | ||

| Consequences of extracting raw materials | Circular solutions such as options that reduce climate risk | ||

| The reputation and role of waste incineration in the circular economy of the future |

Policy/Guidelines

Hafslund has a Group sustainability policy which is founded on Hafslund’s principles relating to Hafslund’s important topic of sustainability.

In “Ethical guidelines and requirements for suppliers”, Hafslund sets the requirement that suppliers must actively work with waste management and phasing out the use of non-renewable resources. Strong emphasis is also placed on reducing negative environmental impact along the entire value chain and that the supplier must ensure sustainable resource extraction.

Principles directly related to “Resource use and circular economy”:

- High resource utilisation shall be a continuous goal. Repair, reuse or recycling must always be considered.

- All companies shall continuously work to reduce Hafslund’s greenhouse gas emissions and impact on nature.

- Continual efforts will be made to increase employee knowledge about the Group’s environmental impact and ongoing initiatives.

Actions

Hafslund places an emphasis on positive impact and opportunities due to the fact that renewable energy production is, in principle, circular. Moving forward, Hafslund must also work actively on how the Group can reduce its negative impact on resource use. This involves reducing the use of primary/virgin raw materials through design and procurement, optimising the life span of assets and components, and ensuring that Hafslund’s assets and facilities can be recycled or reused at the end of their useful life.

In 2024, Hafslund will specify the work related to “Resource use and circular economy”. Hafslund will create an action plan for how the Group can reduce risk and negative impact on the one hand, and how Hafslund can increase positive impact and utilise opportunities on the other. In the plan, Hafslund will take a holistic view, which will include everything from governing documents to how Hafslund will work to reduce the pressure on non-renewable natural resources and raw materials caused by the Group’s business activities.

Below is a summary of some of the actions related to “Resource use and circular economy” that were planned, underway or implemented in 2023:

Circular energy:

The district heating business uses excess heat from waste incineration, sewage and data centres. This is energy that would otherwise be lost.

Bottom ash:

The majority of Hafslund Oslo Celsio’s waste consists of bottom ash (slag) from waste incineration. The ash is further treated by other operators, where metals are extracted and recycled.

Reuse of wind turbines:

Reuse and recycling of turbine blades in offshore wind is an important environmental and circular economy measure. Between 85 and 95 per cent of the materials used in the current turbines can be recycled, but the turbine blades themselves have traditionally gone to waste because they are designed to be extremely difficult to disassemble. Increasing the degree of recycling or reuse of turbine blades is therefore an important task for everyone in the industry. Through Blåvinge, in which Hafslund is a partner with Fred. Olsen Seawind, these are measures that are being looked at to make offshore wind as sustainable and competitive as possible.

Metrics and targets

In 2024, Hafslund will establish specific metrics and targets related to “Resource use and circular economy” as part of the action plan for circular economy and preparation for CSRD reporting in the 2024 annual report.

| Metrics and targets | Result 2023 | Result 2022 | Comment |

|---|---|---|---|

| Increase sorting rate | |||

| Hafslund Eco Vannkraft | 90 per cent | 89 per cent | |

| Hafslund Oslo Celsio | 6.2 per cent | - | New indicator. Low percentage due to large quantity of unsorted bottom ash from waste incineration and district heating |

Indicator table

| Unit | 2023 | 2022 | Comment | ||

|---|---|---|---|---|---|

| Hafslund Eco Vannkraft and Hafslund AS | |||||

| Quantity of hazardous waste | Tonnes | 525 | 8 | ||

| Quantity of non-hazardous waste | Tonnes | 857 | 828 | ||

| Sorting rate | Per cent | 91 | 89 | ||

| Sorting rate large hydropower projects | Per cent | 89 | 91 | ||

| Hafslund Oslo Celsio | |||||

| Quantity of hazardous waste | Tonnes | 17,672 | 17,791 | 17,632 tonnes of this is fly ash from Klemetsrud L1, L2 and L3 and Haraldrud industrial waste boiler | |

| Quantity of non-hazardous waste | Tonnes | 68,963 | 62,138 | 60,433 tonnes of this is bottom ash from Klemetsrud L1, L2 and L3 and Haraldrud food waste boiler | |

| Sorting rate | Per cent | 6.2 | - | New indicator. Sorting rate = Amount of sorted waste/total amount of waste (both sorted and unsorted) X 100 | |

| Quantity of waste treated - Klemetsrud | Tonnes | 321,873 | - | New indicator | |

| Quantity of waste treated - Haraldrud | Tonnes | 44,644 | - | New indicator | |

| Quantity of waste treated at waste incineration plants | Tonnes | 366,517 | 355,686 |

| Unit | 2023 | 2022 | Comment | ||

|---|---|---|---|---|---|

| Hafslund Oslo Celsio | |||||

| Delivered waste heat to the district heating network from the data centre and sewerage | GWh | 100.5 | 80.4 | Waste heat from the data centre and sewage | |

| Surplus heat from incineration of sorted residual waste, including waste heat from REG | GWh | 1,012.9 | 1,016.3 | Produced heat for PV grid from waste heat |